Diesel Fuel Systems Explained

You may not see it at work, but your diesel fuel system is vital to keeping your engine efficient, powerful, and dependable.

This system is responsible for one of your vehicle’s most critical jobs: moving diesel to the engine so combustion can occur. Without it, your car wouldn’t even start.

Today’s diesel fuel systems are designed with incredible precision.

They manage pressure and fuel flow to deliver the balance of performance, economy, and durability drivers rely on.

However, that same accuracy that makes the system so effective also makes it vulnerable. Missed filter replacements or filling up with petrol by mistake can quickly create serious problems and costly repairs.

This guide will explain how your diesel fuel system functions, highlight what can happen if servicing is neglected, and show how timely maintenance can help protect you from expensive repairs.

Concerned about your diesel fuel system? Contact Smith’s of London in Croydon on 020 8674 3377 and let our experts help.

Diesel Fuel System Basics: How It Works

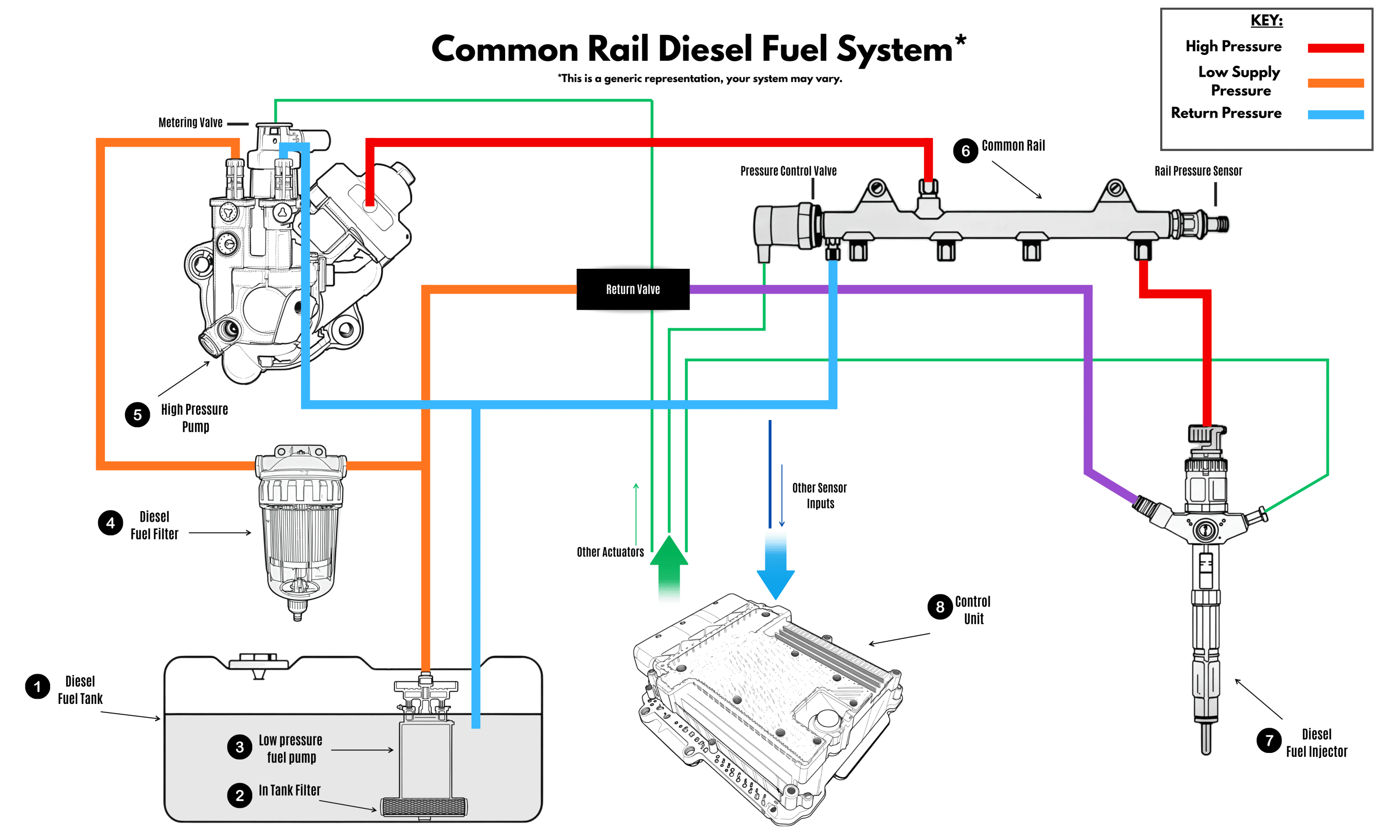

Diesel engines can use different fuel delivery setups, but most modern models are fitted with a common rail diesel fuel system.

While the details may change between designs, the idea is simple: one shared high-pressure rail supplies all the injectors, allowing for consistent fuel flow and accurate injection control.

This system can be broken down into two main halves:

- Low-pressure side: Fuel is drawn from the tank by a pump, filtered to remove dirt and water, and then sent toward the high-pressure pump at the correct supply pressure.

- High-pressure side: The high-pressure pump then compresses the fuel significantly before sending it into the rail, which acts as a reservoir. From there, injectors atomise the diesel into the cylinders in a fine mist at precisely the right moment for combustion.

Put simply, your diesel fuel system guarantees the engine receives clean fuel at the right pressure, exactly when it’s needed.

If you’re not sure what setup your vehicle has, Smith’s of London can help.

Taking an Inside Look at the Diesel Fuel System

With the big picture in mind, it’s time to examine the key parts of the diesel fuel system more closely. Each component has its own responsibility, and they all work together to keep the engine performing as it should.

Diesel Fuel System: The Low-Pressure Section

Fuel Tank & Low-Pressure Fuel Pump

Everything starts in the diesel fuel tank (part 1 of image). A low-pressure pump (part 3 of image) then moves the fuel towards the high-pressure pump, providing a consistent supply to keep the process running without interruption.

Diesel Fuel Filter

Next, the diesel travels through filters (parts 2 and 4 of image) designed to trap dirt and remove water content. This is essential because even small contaminants can cause wear or corrosion in the system’s most precise components.

High-Pressure System

High-Pressure Pump

After filtering, the diesel reaches the high-pressure pump (part 5 of image). Its role is to compress the fuel to around 1800 Bar, which is required for injection.

Metering and Pressure Control Valves

Throughout the process, there are two valves that manage delivery with precision:

- The metering valve determines how much fuel enters the pressurised stage.

- The pressure control valve ensures the rail maintains the correct level for engine performance.

Fuel Rail

Think of the fuel rail (part 6 of image) as a high-pressure storage chamber. It holds fuel at the correct pressure and supplies it evenly to the injectors.

Diesel Injectors

At the end of the process are the injectors (part 7 of image). Their tiny nozzles, the width of a strand of hair, atomise fuel into the cylinders in a fine spray exactly when needed.

Why Diesel Fuel Systems Are Unique

The diesel fuel system is one of the most advanced parts of your vehicle, designed to perform under extreme pressure with absolute precision. A few features make it stand out:

- Precision under pressure: The system links low-pressure delivery with ultra-high-pressure injection, supplying the exact amount of fuel in fractions of a second. It has to cope with pressures many times greater than those in your tyres, ensuring diesel reaches the cylinders as a fine mist for efficient combustion.

- Engineered accuracy: Every component from pumps and filters to the fuel rail and injectors is built to work with pinpoint accuracy. Together, they ensure smoother running, cleaner combustion, and dependable performance.

- Sensitivity to contamination: Because the system is so precise, even a trace of dirt or water can cause wear, corrosion, or other damage. Following manufacturer service intervals and using quality diesel are simple but essential ways to protect it.

These qualities make the diesel fuel system both powerful and finely tuned. With proper care, it delivers consistent performance. If neglected, however, small issues can quickly turn into costly repairs.

To keep your diesel fuel system in top condition, book servicing with Smith’s of London in Croydon.

Our team has the expertise to help you avoid preventable problems and keep your vehicle running reliably.

Consequences of Poor Diesel Fuel System Care

The diesel fuel system operates at extreme pressures, meaning that small amounts of neglect can lead to big consequences. Typical problems include:

- Skipping filter replacements: Fuel filters protect the system from dirt and water. If they’re not changed, contaminants flow through the pumps and injectors, causing wear across the system.

- Substandard fuel: Lower-quality diesel usually contains more impurities and water, which accelerates corrosion in critical components like the pump, rail, and injectors.

- Ongoing contamination: Once debris circulates, it continues to cause damage. Swapping out one component won’t stop the issue unless the source is properly addressed.

Put simply, a filter change costs little compared to the price of repairing widespread damage. So, it’s not worth risking the health of your vehicle to save a few quid by skipping a service.

Misfuelling is another common risk to be aware of. Putting petrol into a diesel tank can cause parts to seize, as petrol doesn’t have the lubrication that diesel does. Even running the engine for less than a second can damage injectors and the high-pressure pump.

If this occurs, don’t start the engine – contact a professional immediately for assistance.

Protecting the Diesel Fuel System from Neglect

The diesel fuel system is designed with advanced engineering, but that precision also means it must be properly maintained. When looked after, it supports reliable performance. Left unchecked, it can fail suddenly and lead to expensive damage.

Protecting it comes down to simple habits:

- Follow your vehicle’s servicing plan

- Change diesel fuel filters when required

- Only use good-quality fuel.

These small steps are far cheaper than repairing system-wide faults.

By keeping your diesel fuel system in good condition, you’ll help your engine stay efficient and dependable for longer.

Still have questions about protecting your diesel fuel system? Call Smith’s of London in Croydon today on 020 8674 3377 to book your service.

Why Drivers Choose Smith’s of London, Croydon

Finding a trustworthy garage for diesel servicing is essential for peace of mind. Here are a few reasons drivers across Croydon and nearby areas choose Smith’s of London:

- Skilled team experienced with all makes and models of diesel vehicles

- Convenient location for Croydon, Beckenham, and Coulsdon drivers

- 12-month parts and labour guarantee on all work for your peace of mind

- Clear and honest advice with no hidden extras

We’re proud of our {{average-rating}}⭐ Google rating from {{review-count}} satisfied customers in Croydon. Book your diesel service with Smith’s of London and experience service you can trust.

FAQ: Diesel Fuel System

- What is a common rail diesel fuel system?

The common rail diesel fuel system has two parts. First, the low-pressure side moves and cleans the fuel. Then, the high-pressure side raises the pressure and stores the fuel in the common rail. From there, advanced injectors atomise the diesel into the cylinders in precise bursts. Because the system allows multiple injections during each cycle, it improves efficiency, power delivery, and engine smoothness compared with older technology. - Why is maintenance important for diesel fuel systems?

Servicing is vital because even small amounts of water or dirt can cause serious damage to the high-pressure pump or injectors. Replacing diesel fuel filters at the right time protects these parts from wear. Routine servicing reduces the risk of sudden breakdowns and avoids costly repairs. - What damages the diesel fuel system?

Common causes include forgetting filter changes, filling with poor-quality diesel, water contamination, and misfuelling with petrol. Even small contaminants can spread throughout the whole system, causing ongoing damage unless the issue is resolved properly. - What happens if petrol goes into a diesel tank?

Petrol lacks the lubricating qualities of diesel. If it reaches the system, it can cause the high-pressure pump and injectors to fail. Even running your engine for a second can spread petrol throughout, making repairs more expensive. The safest course of action is not to turn the key and to have the system professionally drained. - How much does repair cost?

The cost varies. A fuel filter replacement is inexpensive, but pump or injector damage can quickly run into the thousands. Preventative maintenance is always the most cost-effective approach.

Still have questions about your diesel fuel system? Call Smith’s of London, Croydon on 020 8674 3377 for advice or to book your service.